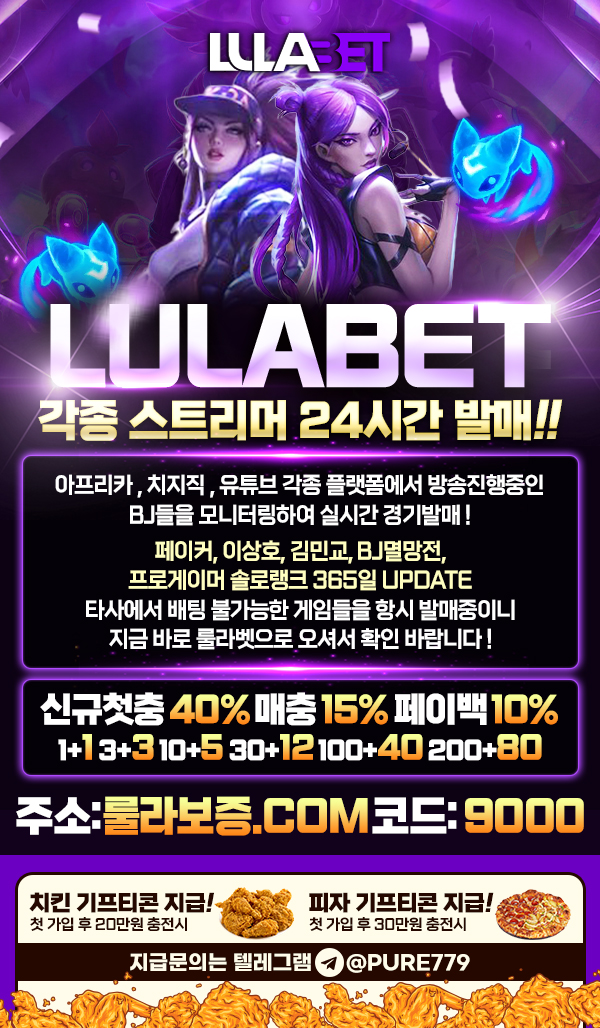

먹튀검증 【룰라보증.com / 가입코드 9000】 롤 배팅

페이지 정보

작성자 vjs9ff 작성일25-04-25 18:10 조회32회 댓글0건관련링크

본문

2025년 2월 TOP1 토토 사이트 추천 - 룰라벳

토토 사이트는 스포츠, 라이브 게임 등 수도 없이 많은 경기들을 발행하여 유저들이 배팅할 수 있도록 온라인 배팅 솔루션을 제공해 주는 사이트입니다. 토토 사이트는 해외 토토 사이트와 사설 토토 사이트 크게 두 가지로 분류할 수 있습니다. 많은 사람들이 사설 토토 사이트를 찾는 이유 중 하나가 다양한 이벤트를 보유하고 있고 배당도 해외 토토 사이트에 비해서 높기 때문입니다.

사설토토사이트의 단점은 도박을 하시다 보면 다수 사고들이 발생하는 걸 쉽게 찾아볼 수 있으실 겁니다. 그래서 더욱더 유저분들께서는 충분한 먹튀검증을 통해 자본력이 풍부하고 오랫동안 운영되었는지를 검토해야 할 것입니다.

안전한토토사이트 룰라벳의 장점

- 첫째: 사설 토토 사이트의 업계 최대 배팅 솔루션 보유 중

- 둘째: 국내 최대 규모의 자본금 보유한 계열사

- 셋째: 100여 가지 이상의 이벤트 진행 중

- 넷째: 광고에 많은 투자를 하고 있음

룰라벳 토토사이트는 자체 제작 솔루션으로 그 어떤 국내 토토사이트와 비교할 수 없을 정도로 업계 최고의 배팅 솔루션을 보유하고 있습니다. 또한, 최소 자본금 300억 이상으로 추정되며, 빠른 고객지원 서비스로 유저들에게 신뢰를 쌓고 있습니다.

수백 가지 토토 사이트를 둘러보시게 되면 수많은 이벤트가 제공되고 있습니다. 룰라벳은 이용 금액에 관계없이 충전 보너스를 제공하며, 다양한 이벤트가 항상 진행 중입니다.

룰라벳은 300여 가지 이상의 코뮤니티에 보증업체로 등록되어 있으며, 다양한 플랫폼에서 광고를 통해 자본력을 보여주고 있습니다.

안전한토토사이트 이용을 위해 위 4가지 방법으로 먹튀 검증을 해보시기 바랍니다.

메이저놀이터 ▶️클릭 룰라벳접속GO◀️

댓글목록

등록된 댓글이 없습니다.